What is U-pgrade™

U-pgrade™ is Elevate’s wholly owned patented beneficiation process that was developed on ore from the Marenica Uranium Project. It is a powerful enabler that has allowed Elevate to capitalise on exploration opportunities as a result of the potential for a much lower project processing cost base.

U-pgrade™ is a beneficiation process that rejects greater than 95% of the mass of uranium ore by utilising commonly used and well understood beneficiation unit processes, which enables the removal of the non-uranium bearing minerals.

Why use U-pgrade™

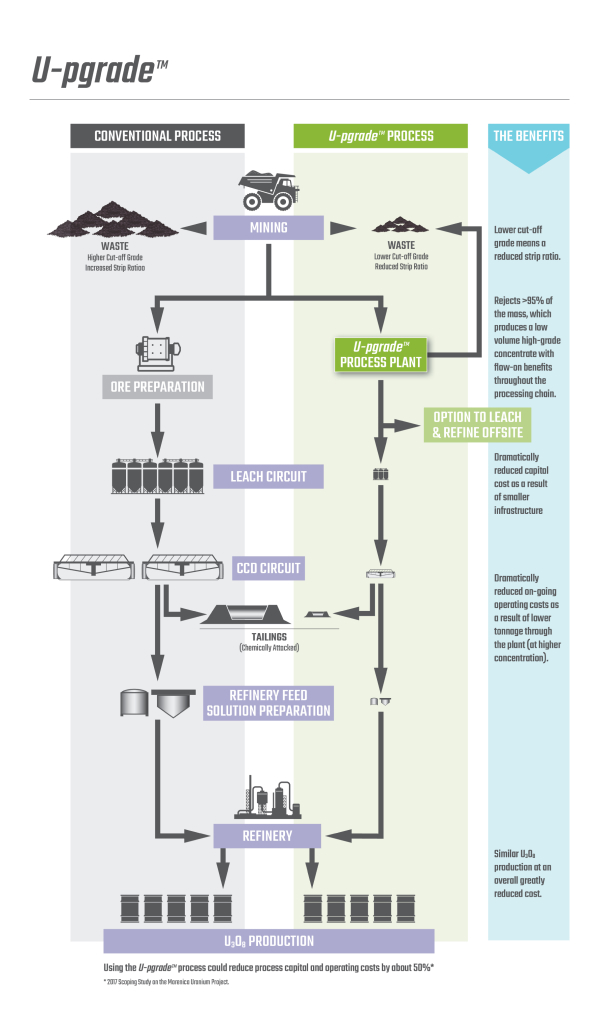

Calcrete hosted uranium ores are characterised by clay and carbonates, with the ore nearest the surface, generally representing about 15% of the resource, containing sulphate minerals. The carbonates consume vast quantities of acid resulting in a high operating cost, which effectively eliminates acid leaching as a process route for these ore types. The alternate leach process is an alkali leach, however, the sulphates consume vast quantities of the alkali reagent meaning that this process route is uneconomic for high sulphate ore, which results in the high sulphate ore, generally 15% of the Namibian resources, being excluded from the process plant feed. Either process route results in high operating costs or exclusion of the near surface ore.

The U-pgrade™ process removes these clay and carbonate minerals producing a concentrate that is suitable for acid leaching, which is, the lower temperature and lower cost leach process. Leaching in acid means that the high sulphate ore can be processed, thereby improving project economics and bringing that ore into the mineable reserve and increasing the size or life of the project.

Transforming project economics

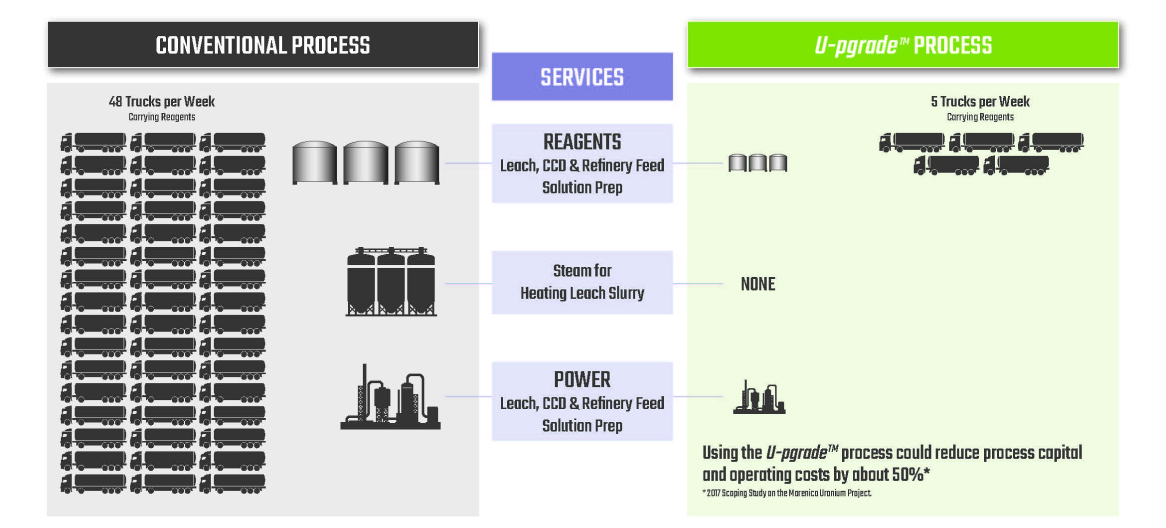

Using U-pgrade™ to reject more than 95% of the ore mass, prior to leaching, produces a low-volume high-grade concentrate. From a capital cost perspective this means less than 5% of the ore goes through the leach plant, thereby reducing the physical size of the plant and hence the capital cost. From an operating cost perspective, it means a reduction in power consumption, reagent (acid included) usage, wear and tear and ultimately a smaller tailings dam. Combined, these reductions mean massive project cost savings.

A 2017 Scoping Study (“Study”) on the Marenica Uranium Project found that by using the U-pgrade™ process, capital and operating costs could be reduced by ~50% compared to conventional processing.

Production of a low mass concentrate provides additional leach / refining options. Assuming the U-pgrade™ concentrate is transported off site to a third party’s existing leach / refinery for processing there is no need to build a leach circuit, tailings dam or refinery on site which will further reduce capital costs.

U-pgrade™ operating costs are predominantly tonnes based, therefore doubling the mined ore grade potentially halves the unit cost per pound of uranium in the ore. Further increases in mined grade are expected to further reduce unit cost per pound of contained uranium.

Where can U-pgrade™ be used?

U-pgrade™ is potentially an industry leading and economically transformational beneficiation process for upgrading surficial uranium ores.

This breakthrough process was developed on ore from Elevate’s Marenica Uranium Project in Namibia and subsequently, testwork has been undertaken on ore samples from four other Namibian calcrete resources.

In summary, Elevate has demonstrated, in bench scale testwork on ore from the Marenica Uranium Project, that the U-pgrade™ beneficiation process;

- Concentrates the uranium by a factor of 50

- Increases ore grade from 93 ppm to ~5,000 ppm U3O8

- Rejects ~98% of the mass prior to leaching

- Produces a high-grade concentrate in a low mass of ~2% (leach feed)

- Rejects acid consumers

- Potentially reduces operating and capital costs by ~50% compared to conventional processing.

- Similar test results have been achieved in fresh and sea water, which is particularly beneficial in a dry environment such as Namibia.

Beyond application of U-pgrade™ at the Marenica Uranium Project, Elevate has determined, through bench scale testing, that ores from all calcrete hosted deposits in Namibia and Australia, are amongst those that are amenable to the U-pgrade™ process.

Elevate believes that U-pgrade™ is not limited to surficial uranium ores, and could be used in part or its entirety, on other uranium ore types. An example is the successful outcome of U-pgrade™ testwork on the Angela Project.

What is the environmental impact of U-pgrade™?

The U-pgrade™ process is a physical beneficiation process. As a result of up to 50 times physical reduction in ore mass, use of chemicals in the leach process are significantly reduced. This reduction results in reagent consumption of less than 5% compared to conventional processes, thus there is far less impact on the environment. There is <5% of the reagents transported and the tailings dam is <5% of the volume of a conventional process.

The acid consuming mineral (calcite), which is removed during the U-pgrade™ process could be recombined with the reduced leach tailings to neutralise the remaining acid and precipitate any soluble metals, rendering the tailings inert, thereby providing an added environmental benefit.

Processing the U-pgrade™ concentrate at an existing refinery further reduces the environmental impact as the refinery will have established reagent transport corridors and the leach tail would be deposited into an existing tailings facility.